Introduction

Pyridine is a widely used chemical compound found in a variety of products, including pesticides, drugs, and rubber.

Details

Pyridine is a widely used chemical compound found in a variety of products, including pesticides, drugs, and rubber. Its versatility has led to its widespread adoption in different industries. Pyridine is a heterocyclic organic compound that contains six carbon atoms and one nitrogen atom. It is considered a colorless and highly flammable liquid that has a strong, fish-like odor. In this blog post, we will explore the science behind pyridine, examine its production and processing techniques, and discuss its application and safety practices.

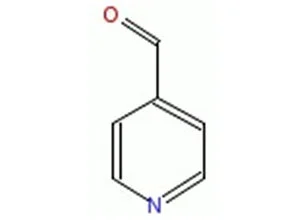

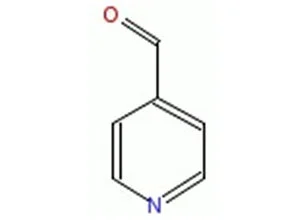

1.Formulation and Composition: The Science Behind PyridinePyridine has a unique chemical structure that sets it apart from other organic compounds. In its formulation and composition, pyridine is an organic heterocyclic compound that forms a six-membered ring with a nitrogen atom. The chemical identity of pyridine is C5H5N, which is also known as azabenzene. Pyridine's structure is essential for its pharmacological activity and use in various industries. Its boiling point ranges between 115°C and 120°C, and its density is 0.9819 g/cm3. The odor of pyridine is strong and somewhat unpleasant, which necessitates the use of protective gear during the handling process.

2.Production Techniques: How Pyridine is ManufacturedThe production of pyridine is essential to meet the growing demand in different industries. Pyridine can be produced using different methods, including the Bönnemann method, Chichibabin method, and modified Chichibabin method. The Bönnemann method involves the homocoupling of acetylene, which results in the formation of 1,4-butadiyne. The acetylene undergoes polycondensation with formaldehyde and formic acid to produce pyridine. The Chichibabin method involves the reaction of acetaldehyde with ammonia, with the aid of catalysts such as iron, nickel, or cobalt. The modified Chichibabin method uses acetaldehyde and ammonia in the presence of different solvents such as diethyl ether, methyl glycol, or triethyl.

3.Quality Assurance: Ensuring the Standard of PyridineQuality assurance is an essential aspect of pyridine production, ensuring that the end product is of high quality, fit for the intended purpose, and meets the required industry standards. Quality control measures for pyridine involve rigorous testing to ensure that the end product is free from impurities, contaminants, and meets the specified purity levels. The quality assurance process also includes ensuring that the production facilities adhere to safe handling processes, environmental regulations, and ethical practices. Quality assurance is critical in the production of pyridine medication, ensuring that the medication is pure, stable, and effective in treating specific health conditions.

4.Application Techniques: Best Practices for Using PyridinePyridine is a versatile chemical with various applications in different industries, and its proper use is critical in ensuring safety and effectiveness. Some of the industries that use pyridine include pharmaceuticals, agrochemicals, and rubber. Pyridine applications include its use as a solvent for organic compounds, as an intermediate in the production of azo dyes, in the synthesis of pharmaceuticals, insecticides, and herbicides. The proper use of pyridine in each industry is essential to prevent harm to the user, environment, and the final product. Some of the best practices for using pyridine include the use of proper protective gear, ensuring proper ventilation when handling the chemical, and adhering to regulatory guidelines.

5.Safety and Compliance: Meeting International Standards with PyridineSafety and compliance are critical aspects of pyridine production, ensuring that the end product is safe for use in different industries. Pyridine is a hazardous substance with improper handling that can lead to serious health complications. Ensuring that production facilities maintain safe handling processes for pyridine is essential in ensuring the safety of workers and the environment. Regulatory bodies have set standards for pyridine production and use that manufacturers must adhere to in meeting international standards. These standards include guidelines on proper handling, transportation, storage, and disposal of pyridine.In conclusion, pyridine's versatility has led to its widespread use in various industries, making it a crucial component in product formulation and manufacturing processes. The production and processing of pyridine require adherence to set standards to ensure that the end product is of high quality, safe, and effective in its intended use. Pyridine has numerous applications, and proper handling of the chemical to ensure safety is paramount in each industry. By adhering to international safety and regulatory standards, pyridine production facilities can produce a product that is safe for use and meets the required industry standards. For inquiries regarding pyridine, please contact us at Tel: +86 13188799390 or E-mail: [email protected].